Advanced XYZ Axis PCB Soldering Machine for USB Connector Soldering with Iron Tip

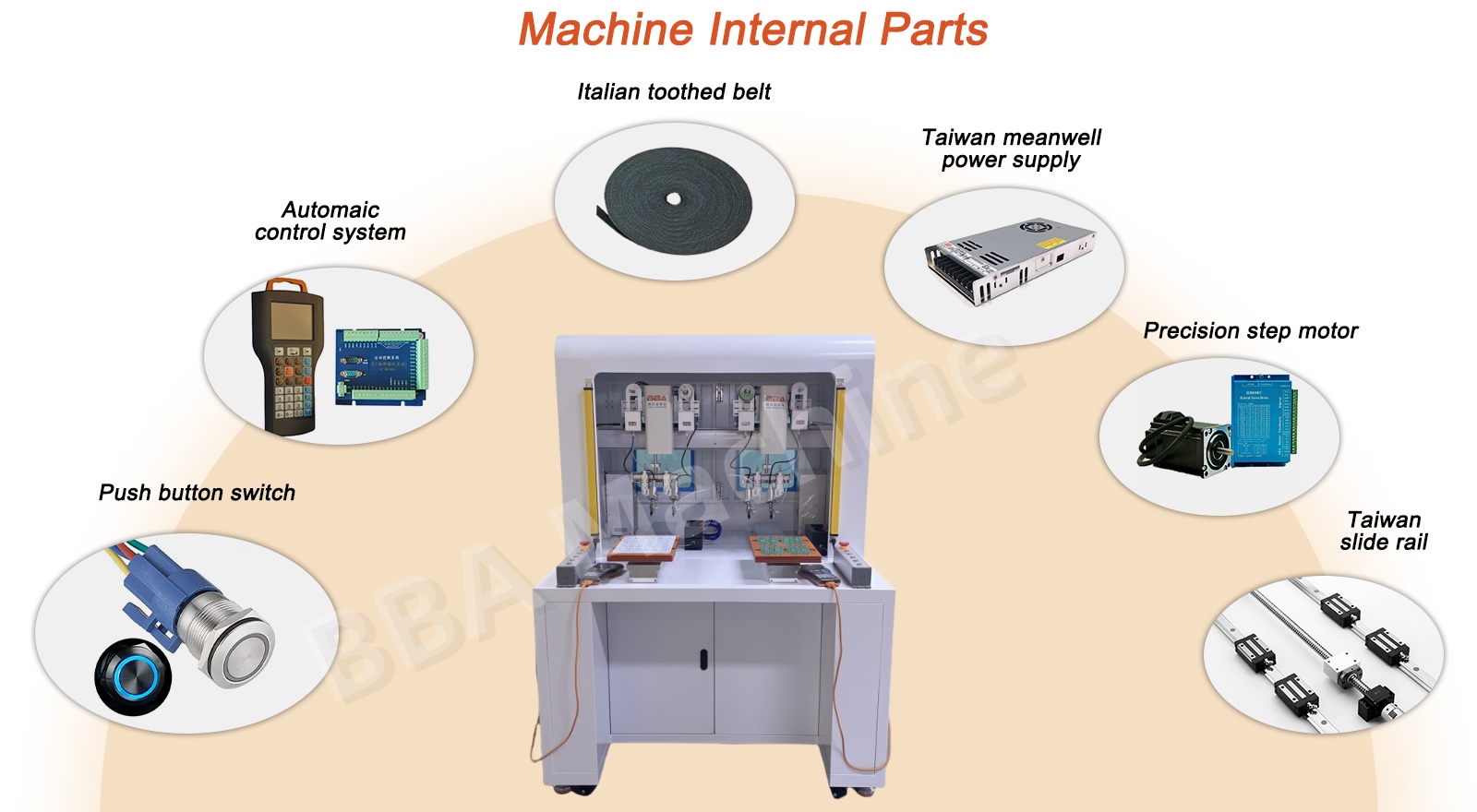

In 3C electronics manufacturing, USB connector soldering requires precise motion control and targeted heat application, especially for miniaturized USB-C ports and dense PCB layouts. The Advanced XYZ Axis PCB Soldering Machine for USB Connector Soldering with Iron Tip meets these demands, integrating the multi-directional flexibility of XYZ Axis motion, the targeted heating ofIron Tip soldering, and advanced control technology to deliver consistent, high-quality results for USB-A, USB-C, and Micro-USB assembly.

XYZ Axis Motion: Flexible Access for Complex USB Soldering

The XYZ Axis motion system is the core of the machine’s adaptability in USB connector soldering. Unlike single or dual-axis equipment, it enables three-dimensional linear movement, allowing the Iron Tip to easily reach hidden or angled solder points—such as the inner pins of USB-C connectors or the edge-mounted USB ports on slim devices. With ±0.01mm positional accuracy and adjustable speed (0.3–5mm/s), the system navigates precisely between PCB components, avoiding interference with adjacent parts. This flexibility is crucial for handling diverse USB connector layouts, from standard pin arrays to complex shielded USB modules, ensuring each solder joint is targeted accurately.

Iron Tip: Targeted Heating for USB Component Protection

The specialized Iron Tip is tailored for the heat sensitivity of USB connector soldering. It features rapid temperature response (200°C–450°C) and localized heat application, minimizing thermal spread to protect delicate USB plastic housings and nearby electronic components. The tip’s ergonomic designs—including conical, chisel, and hoof shapes—adapt to different USB solder points, from tiny pin pads to large shield connections. With anti-oxidation coating, the tip maintains stable heat transfer and durability, reducing replacement frequency even in high-volume production. Closed-loop temperature control ensures consistent heat output, preventing cold joints or overheating damage to USB connectors.

| Product name | Applicable industries |

| robotic soldering machine | Electro-Acoustic |

Advanced USB-Centric Features: Streamlining Production

The machine’s advanced functions are optimized for USB connector soldering workflows. It can store soldering parameters for 60+ USB models, enabling quick changeovers between smartphone, tablet, and power bank production lines. The intuitive touchscreen control allows easy programming of soldering paths, with built-in templates for common USB connectors. Optional vision recognition enhances precision by automatically compensating for minor PCB placement deviations. Its compact design integrates seamlessly into existing SMT lines, matching with automatic PCB feeding systems to boost production efficiency. Built-in fault alerts for tip wear or temperature anomalies minimize downtime, ensuring continuous operation.

In summary, the fusion of XYZ Axis flexibility, Iron Tip targeted heating, and advanced USB-focused features makes this machine indispensable for USB connector soldering. It delivers the accuracy, component protection, and efficiency needed to meet the strict quality standards of modern 3C electronics manufacturing.