Views: 0 Author: BBA AUTOMATION Publish Time: 2025-07-09 Origin: BBA AUTOMATION

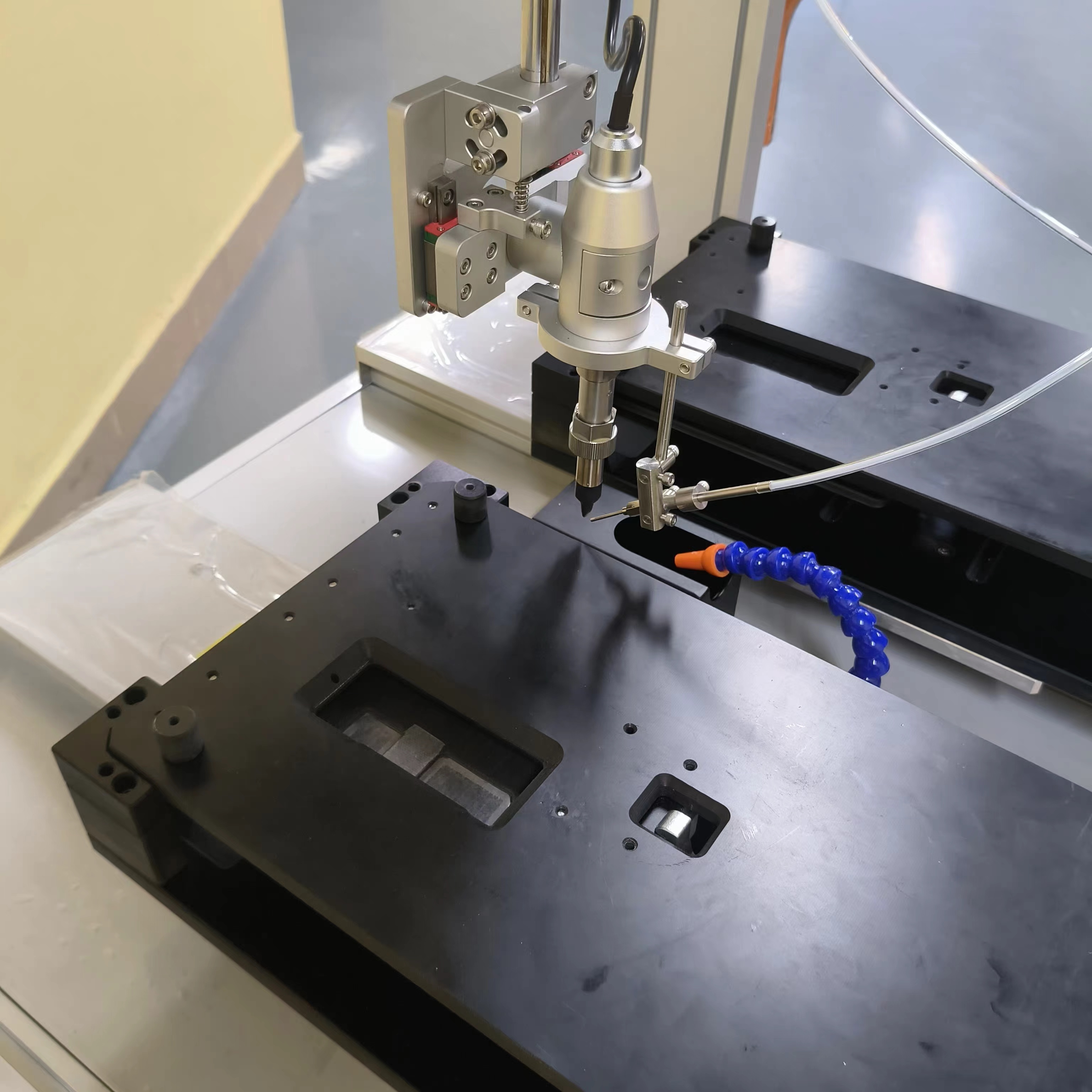

In modern manufacturing, automatic soldering equipment plays a crucial role in ensuring precision, efficiency, and consistency in soldering processes. With industries demanding higher production rates and flawless electronic assembly, automated solutions have become indispensable. This guide explores the key features, benefits, and applications of advanced soldering systems, helping manufacturers optimize their operations.

Automatic soldering equipment is designed to improve production speed and quality. Some of its essential features include:

Programmable Control Systems – Allow precise adjustments for soldering temperature, speed, and positioning.

Multi-Axis Operation – Ensures flexibility in handling complex soldering tasks with robotic precision.

Solder Wire Feeding Mechanism – Automatically feeds the solder wire for consistent joint formation.

Temperature Regulation – Prevents overheating and ensures uniform soldering quality.

Automated Flux Application – Enhances solder flow and improves bond strength in electronic components.

| Product Title | Designed for industry use |

| Tabletop Soldering System | Automotive Electronics |

Implementing automatic soldering equipment brings numerous advantages to manufacturing processes:

Higher Efficiency – Reduces human error and speeds up the soldering process, increasing overall production output.

Improved Soldering Quality – Ensures precise and consistent solder joints, minimizing defects.

Reduced Labor Costs – Eliminates the need for extensive manual labor, cutting operational expenses.

Enhanced Safety – Reduces exposure to high temperatures and harmful fumes, creating a safer work environment.

Versatility in Applications – Suitable for PCB soldering, automotive electronics, and industrial manufacturing.

Automatic soldering equipment is widely used across multiple sectors, including:

Electronics Manufacturing – Essential for PCB assembly and micro-component soldering.

Automotive Industry – Ensures durable connections in automotive electronic systems.

Medical Devices – Provides high-precision soldering for delicate medical electronics.

The adoption of automatic soldering equipment is transforming modern manufacturing by enhancing efficiency, reliability, and precision. As technology advances, these systems continue to revolutionize electronic assembly, making them a vital asset for industries looking to improve production quality and automation.