Views: 0 Author: BBA AUTOMATION Publish Time: 2025-07-30 Origin: BBA AUTOMATION

In the fast-paced world of electronics manufacturing, precision and efficiency are critical. Electronic component soldering plays a vital role in ensuring the reliability and performance of electronic devices. As technology advances, so do the methods and tools used in soldering, paving the way for smarter, faster, and more accurate production processes. Let’s take a closer look at how electronic component soldering is shaping the future of manufacturing.

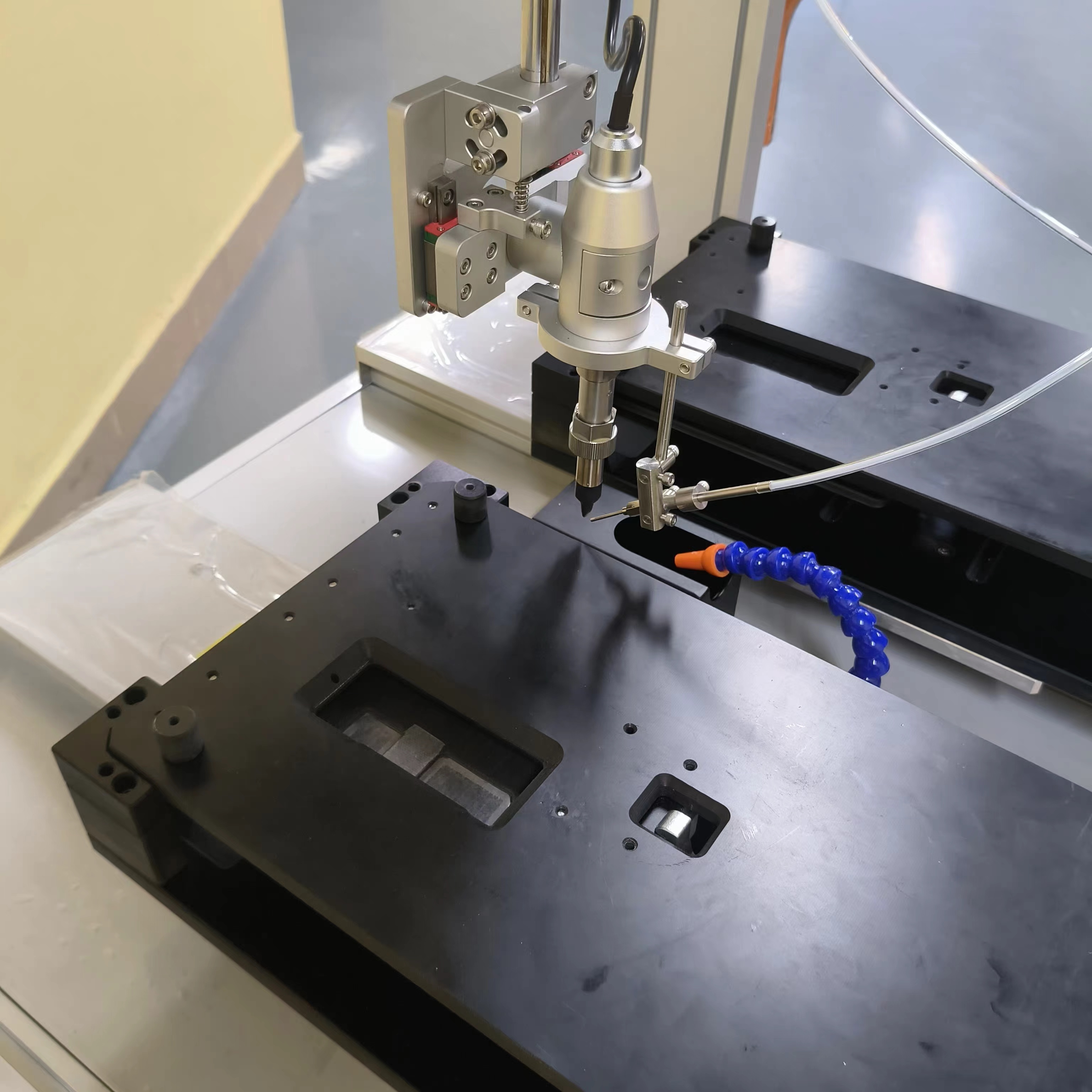

The development of automated soldering equipment has transformed manufacturing lines. Machines like soldering robots and reflow soldering systems offer unmatched precision and consistency. These advanced systems ensure that each joint is made with exact temperature control and optimal solder application, reducing human error and enhancing product quality.

In addition, wave soldering and selective soldering techniques allow manufacturers to handle complex PCB assemblies with speed and accuracy, making them essential in high-volume production environments.

Electronic component soldering equipment streamlines assembly lines, significantly reducing production time. Automated soldering systems can handle multiple soldering points simultaneously, increasing output without sacrificing quality. This high-speed efficiency not only boosts productivity but also helps minimize labor costs.

Moreover, programmable soldering profiles ensure that each product receives the exact soldering treatment required, eliminating the need for constant adjustments and ensuring consistency across batches.

As electronic devices become smaller and more complex, precision soldering becomes even more critical. Vision systems integrated into modern soldering machines allow for real-time inspection and error detection, ensuring that even the smallest components are placed and soldered with perfect accuracy.

This level of quality control minimizes defective products and reduces rework costs, leading to higher customer satisfaction and long-term reliability of electronic devices.

| Product Identifier | Applicable Industries |

| desktop soldering robot | Circuit Boards |

Advanced soldering equipment is designed to reduce waste and conserve energy. Efficient solder consumption and low energy usage help manufacturers cut costs while contributing to environmental sustainability goals.

Additionally, lead-free soldering options and fume extraction systems promote safer working environments for operators, making the workplace both efficient and safe.

The future of manufacturing lies in innovative and efficient soldering solutions. With advanced technology, improved precision, and higher productivity, electronic component soldering ensures the reliability and performance of modern electronic devices. By investing in cutting-edge soldering equipment, manufacturers can stay competitive and prepared for the evolving demands of the electronics industry.