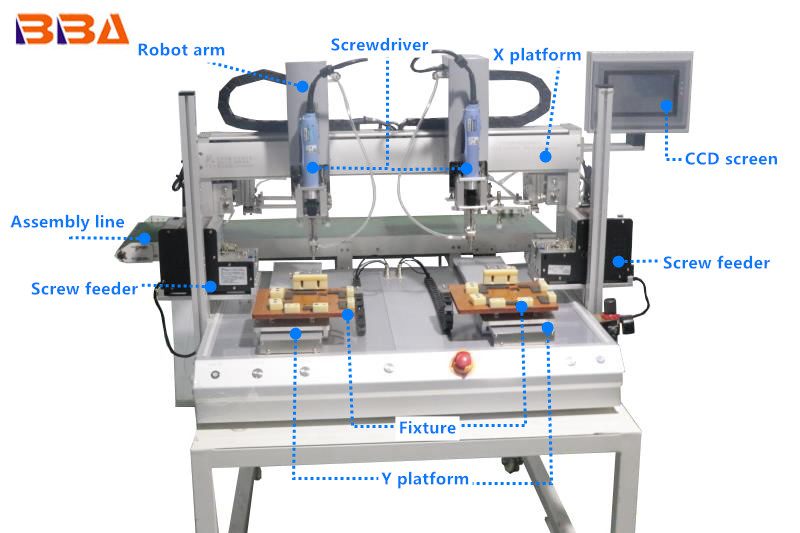

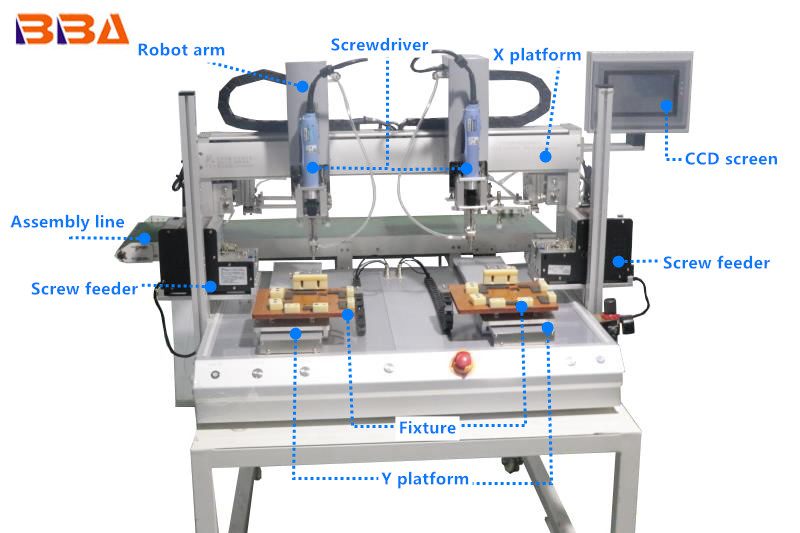

High Torque Screw Fastening Machine with Positioning System for Mobile Phone Assembly

Modern mobile phone assembly balances delicate components with structural durability—especially for parts like metal frames, camera modules, and battery brackets that require secure fastening. The high torque screw fastening machine with positioning system meets this dual demand, merging robust torque output with pinpoint accuracy to ensure reliable, damage-free assembly of smartphones and foldable devices.

High Torque: Secure Fastening for Structural Phone Parts

The machine’s high torque capability (5–20 N·m) addresses a key challenge in mobile phone assembly: securing load-bearing components without compromise. Metal frames, waterproof gaskets, and heat sinks for high-performance chips need firm clamping to withstand daily use, yet traditional tools often lack the torque to fasten them consistently. This machine delivers steady, adjustable torque, ensuring screws hold tight against vibration or impact—critical for preventing frame deformation or water ingress. Unlike low-torque tools, it eliminates "loose screw" defects that lead to post-sales repairs, enhancing product reliability.

Positioning System: Precision to Protect Delicate Components

Complementing its torque, the integrated positioning system guarantees ±0.02mm accuracy—essential for avoiding damage to nearby delicate parts like OLED screens or circuit boards. Using laser guidance and optical recognition, it automatically locates screw holes even if phone components have minor placement deviations. For example, when fastening screws to a camera module adjacent to a fragile fingerprint sensor, the system ensures the fastening head aligns perfectly, preventing scratches or pressure damage. It also records positioning data for each screw, enabling traceability—a growing requirement in high-end mobile phone assembly.

Mobile-Centric Design: Adaptability for Diverse Models

Tailored for mobile phone assembly, the machine balances versatility with usability. It accommodates screw sizes from M1.2 to M3.5—standard for most smartphones—and features quick-change tooling to switch between screw types in 60 seconds. The intuitive control panel lets operators store torque and positioning parameters for 100+ phone models, supporting fast changeovers between flagship, mid-range, and foldable devices. Its compact design integrates seamlessly into existing assembly lines, while built-in error alerts (for misaligned holes or over-torque) minimize downtime. For manufacturers, this adaptability means the machine can grow with changing product portfolios.

In summary, the fusion of high torque strength, positioning system precision, and mobile-focused design makes this machine indispensable for mobile phone assembly. It delivers the security and accuracy needed to meet the strict quality standards of the consumer electronics industry.