Views: 0 Author: BBA AUTOMATION Publish Time: 2025-05-13 Origin: BBA AUTOMATION

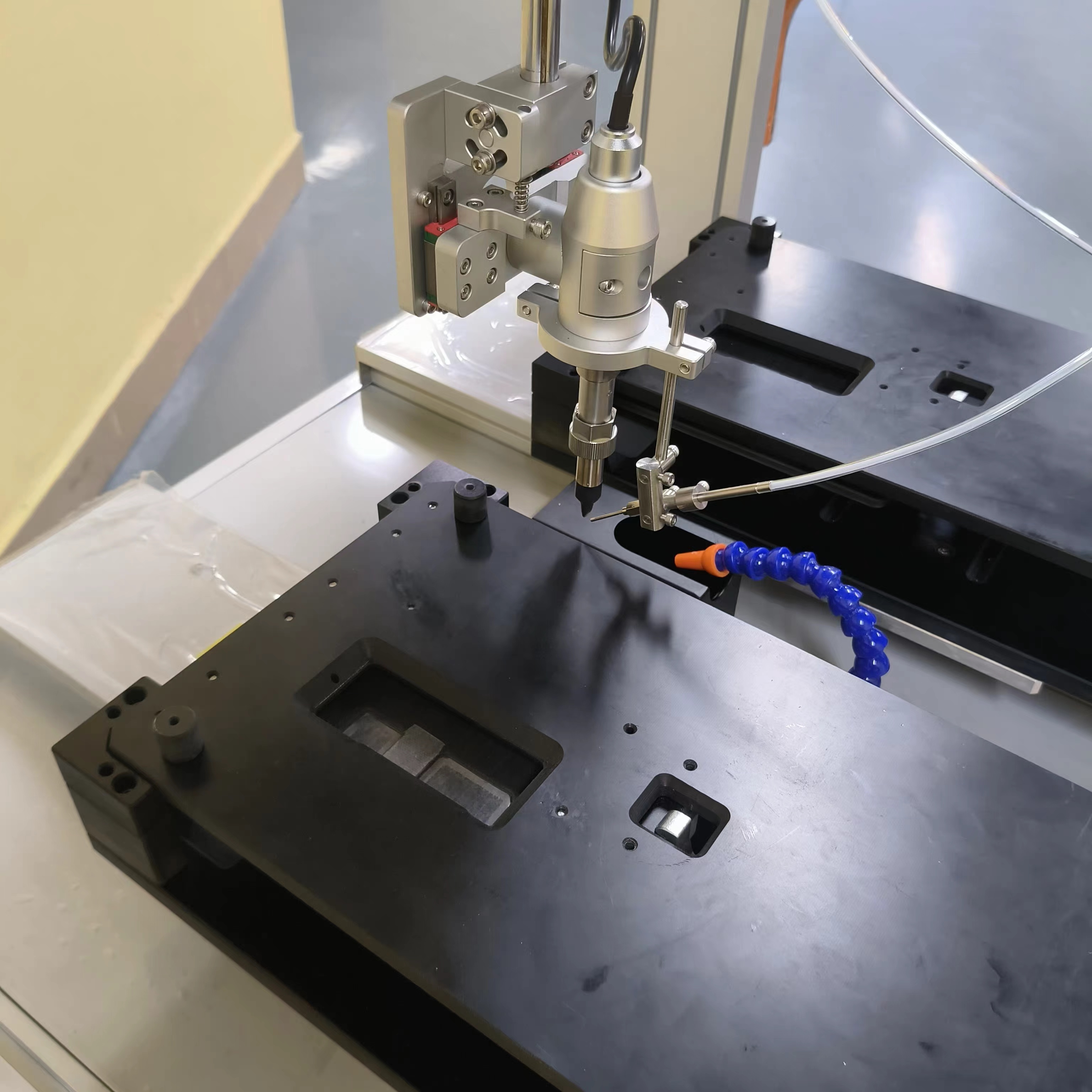

As manufacturing demands evolve, micro soldering technology is emerging as a game-changing solution for assembling increasingly miniaturized components. This advanced method enables highly precise soldering of parts too small or delicate for traditional techniques. From microchips to fine wiring, the technology supports the intricate connections necessary in modern electronic devices, especially where accuracy is non-negotiable.

In industries such as aerospace, medical, and consumer electronics, the trend toward compact, multifunctional devices continues to grow. Micro soldering plays a crucial role in enabling this evolution by offering ultra-fine control over soldering points. It supports complex circuit designs, densely packed PCBs, and emerging technologies like wearable electronics. Without it, achieving the required level of miniaturization would be nearly impossible.

| Product Name | Applicable industries |

| Tabletop Soldering System | Electronics |

Despite its detailed focus, micro soldering technology does not compromise on efficiency. With modern automation and heat control systems, soldering can be performed faster and with greater consistency than manual approaches. This results in not only higher throughput but also reduced error rates, leading to significant savings in rework and quality control.

The precision of micro soldering is especially vital in high-reliability applications where failure is not an option. In sectors like automotive safety systems or medical implants, a secure solder joint can directly impact performance and safety. Micro soldering delivers the confidence manufacturers need to ensure long-term reliability under extreme conditions.

Micro soldering technology represents the intersection of precision engineering, advanced materials, and intelligent automation. As products become smaller, smarter, and more connected, this technology will only grow in importance. Manufacturers who invest in micro soldering are not just improving current production—they are preparing for the future of high-tech manufacturing with a toolset built for accuracy, speed, and innovation.