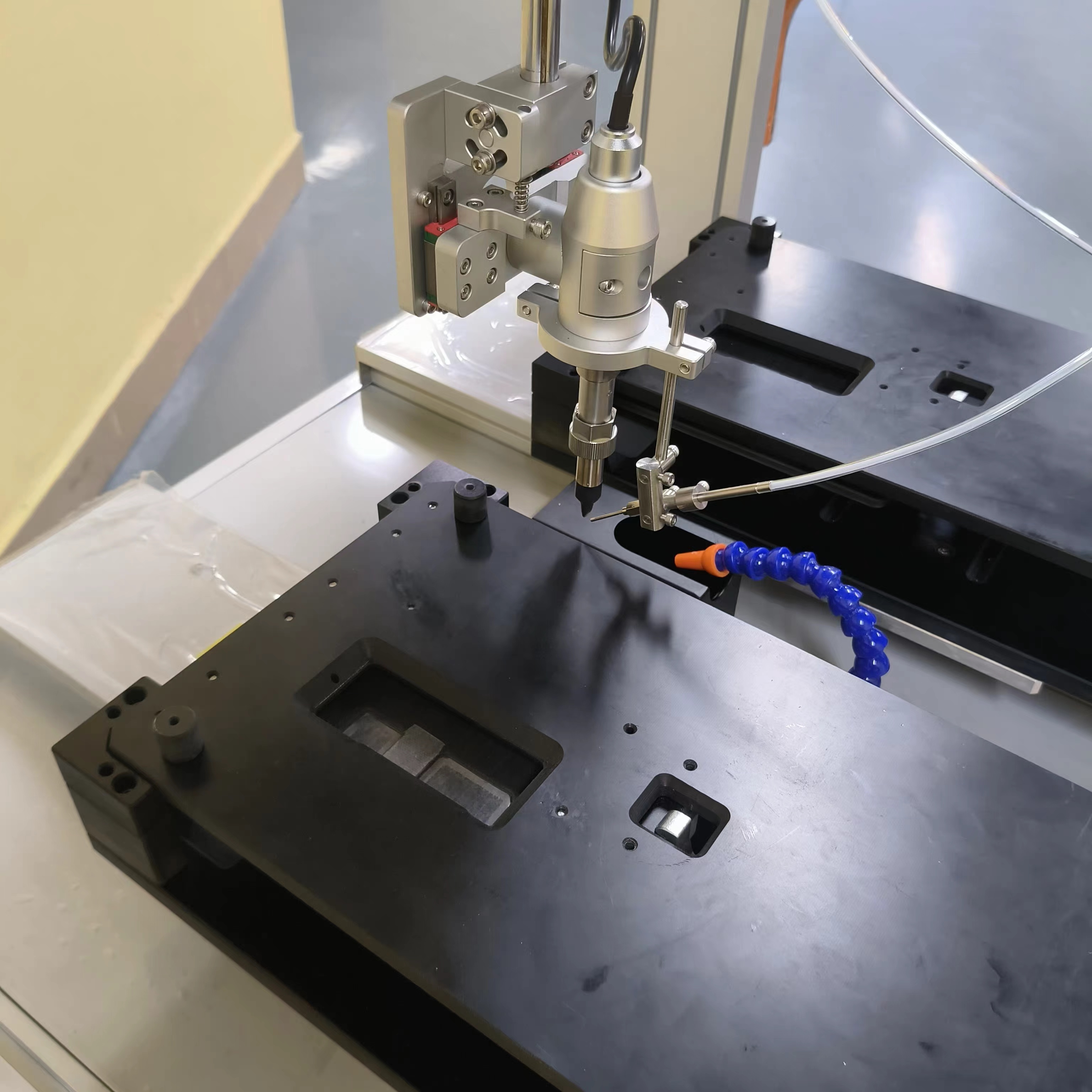

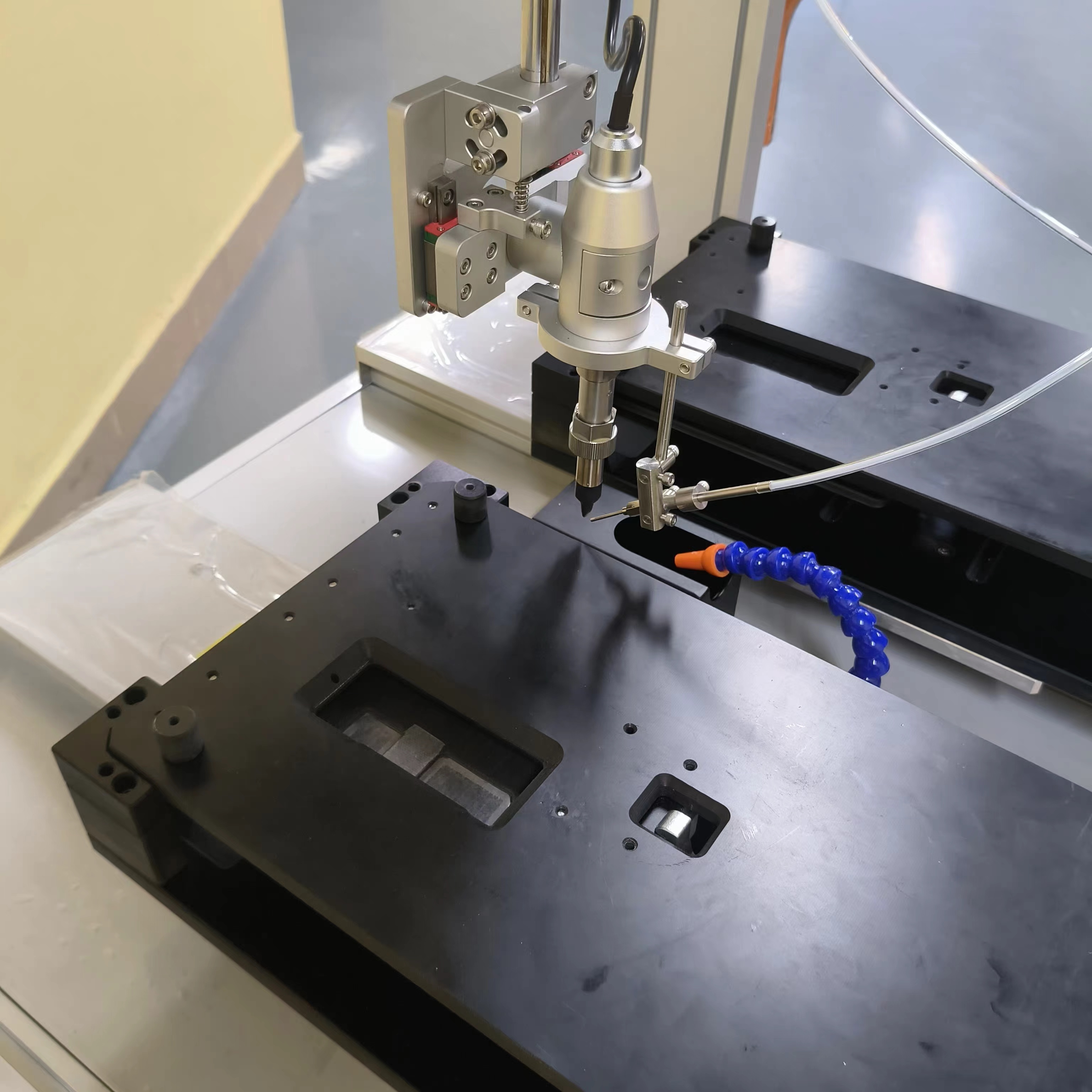

Advanced Gantry Type PCB Soldering Machine for Electronic Components with Five Axis Motion

As electronic components grow smaller and PCB layouts more complex, traditional soldering equipment struggles to meet precision and efficiency demands. The advanced gantry type PCB soldering machine with five axis motion addresses this gap, integrating stable gantry architecture and multi-dimensional movement to deliver unmatched performance in soldering resistors, ICs, connectors, and other critical parts.

Gantry Type Design: Stability for High-Volume Production

The gantry type structure is the foundation of the machine’s reliability, featuring a rigid beam framework that minimizes vibration during operation. Unlike cantilever designs prone to deflection, the gantry system ensures consistent soldering head positioning even at high speeds, making it ideal for mass production of electronic components. It supports large PCB panels (up to 1200x800mm) and can be integrated into inline assembly lines, with conveyor systems that enable continuous material flow. This stability reduces defect rates by 30% compared to conventional machines, while the gantry’s open design simplifies maintenance and PCB loading/unloading.

| Product Name | Suitable for various industries |

| automated soldering machine | Production Industries Welding |

Five Axis Motion: Precision for Complex Component Layouts

The five axis motion system is a game-changer for intricate PCB soldering tasks. Beyond the standard X, Y, Z axes, it adds A (rotation) and C (swivel) axes, allowing the soldering head to adjust angles and orientations freely. This flexibility is critical for soldering components in tight spaces—such as BGA chips or side-mounted connectors—or those with non-planar pads. With positioning accuracy of ±0.02mm, the five axis system ensures each solder joint is uniform and reliable, even for 01005-sized micro-components. It also reduces setup time for custom PCBs, as the axes can be programmed to adapt to new layouts without mechanical adjustments.

Tailored for Electronic Components: Efficiency and Versatility

Engineered specifically for electronic components, the machine combines precision with productivity. It features temperature-controlled soldering tips (180°C–480°C) that adapt to different component materials, from heat-sensitive diodes to robust power connectors. The integrated solder feed system delivers precise wire amounts, minimizing waste and ensuring consistent joint quality. User-friendly software allows operators to store hundreds of soldering programs, enabling quick switches between product models—essential for small-batch or customized production. Additionally, built-in vision inspection (optional) verifies solder joints in real time, further reducing rework and enhancing quality control.

In summary, the fusion of gantry type stability, five axis motion precision, and component-focused design makes this machine indispensable for modern PCB soldering. It meets the industry’s need for speed, accuracy, and versatility, helping manufacturers stay competitive in the fast-evolving electronics market.