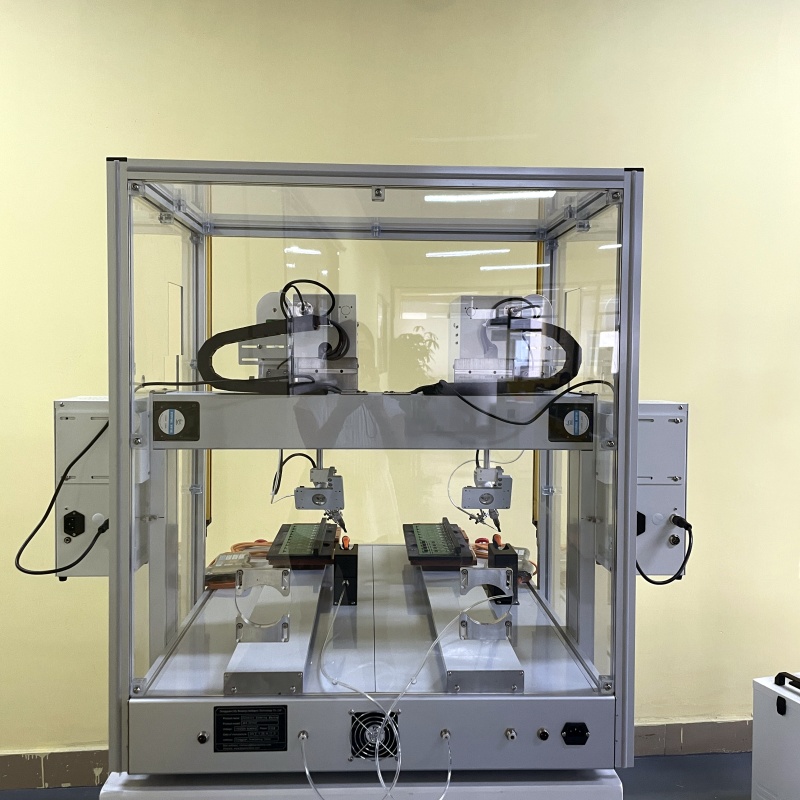

Automatic Soldering Machine Inline Style with Tin Feeding System, Ideal for Electronic Components

In the mass production of electronic components, consistency, efficiency, and precision are non-negotiable. The inline style automatic soldering machine with tin feeding system emerges as a core production asset, seamlessly integrating into assembly lines to handle soldering tasks for resistors, capacitors, connectors, and other tiny parts. Its unique structure and automated functions address the pain points of traditional soldering, elevating productivity while ensuring stable quality.

Inline Style: Seamless Integration into Mass Production Lines

The inline style design is tailored for high-volume manufacturing, allowing the machine to connect directly with upstream and downstream equipment—such as PCB conveyors and inspection tools—forming a continuous workflow. Unlike standalone machines that require manual material transfer, this inline configuration eliminates downtime between processes, cutting overall production cycle times by up to 35%. It adapts to different conveyor speeds and PCB sizes, making it suitable for diverse electronic components production, from consumer electronics to industrial control boards. The compact layout also optimizes factory floor space, a key advantage for dense production environments.

| Product name | Applicable to multiple sectors |

| robotic soldering machine | Production Industries Welding |

Tin Feeding System: Automated Precision for Uniform Joints

The built-in tin feeding system is a game-changer for soldering accuracy. It automatically delivers pre-calibrated amounts of solder to the soldering tip, replacing manual tin feeding that often leads to uneven solder volume or waste. The system adjusts tin feed speed and quantity based on preset parameters, ensuring each solder joint—whether for a 0402-sized resistor or a larger connector—has consistent shape and conductivity. This automation not only reduces material waste by 20% but also eliminates human errors like cold joints or solder bridges, which are costly to rework in electronic components manufacturing.

Tailored for Electronic Components: Reliability and Versatility

As a specialized automatic soldering machine, it excels at the delicate demands of electronic components. Equipped with high-precision temperature control (180°C–480°C) and a responsive soldering tip positioning system (±0.02mm accuracy), it handles heat-sensitive components without causing damage. The machine supports various solder wire types, including lead-free options, complying with global electronics standards. Its user-friendly interface allows operators to store multiple soldering programs, enabling quick switches between different component models. Built-in sensors monitor soldering quality in real time, alerting to anomalies like tip wear or insufficient tin, further safeguarding production consistency.

In summary, the combination of inline style efficiency, tin feeding system precision, and electronic component-focused design makes this machine indispensable. It transforms soldering from a labor-intensive, error-prone task into a reliable, automated process—helping manufacturers meet the growing demand for high-quality electronic products while optimizing costs.