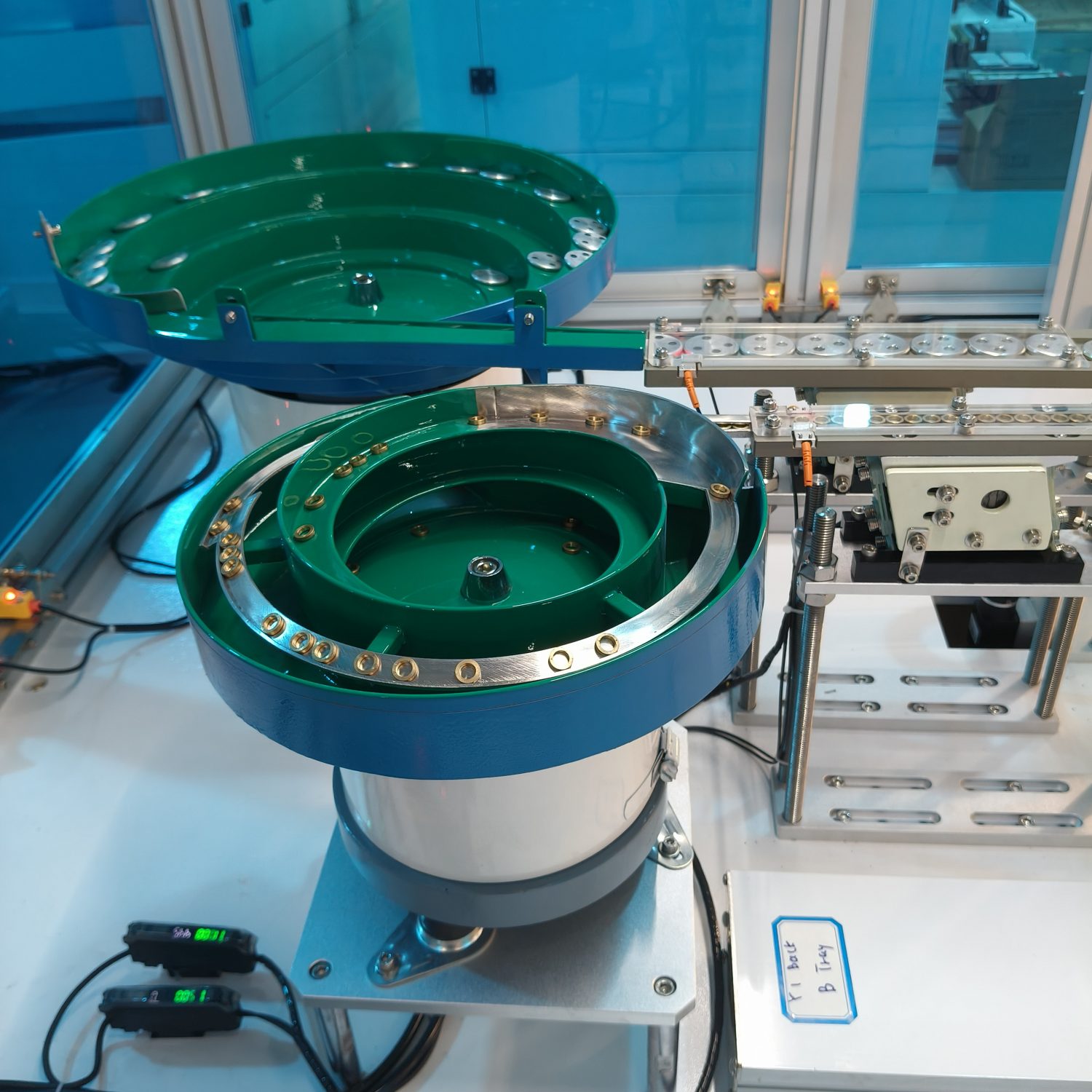

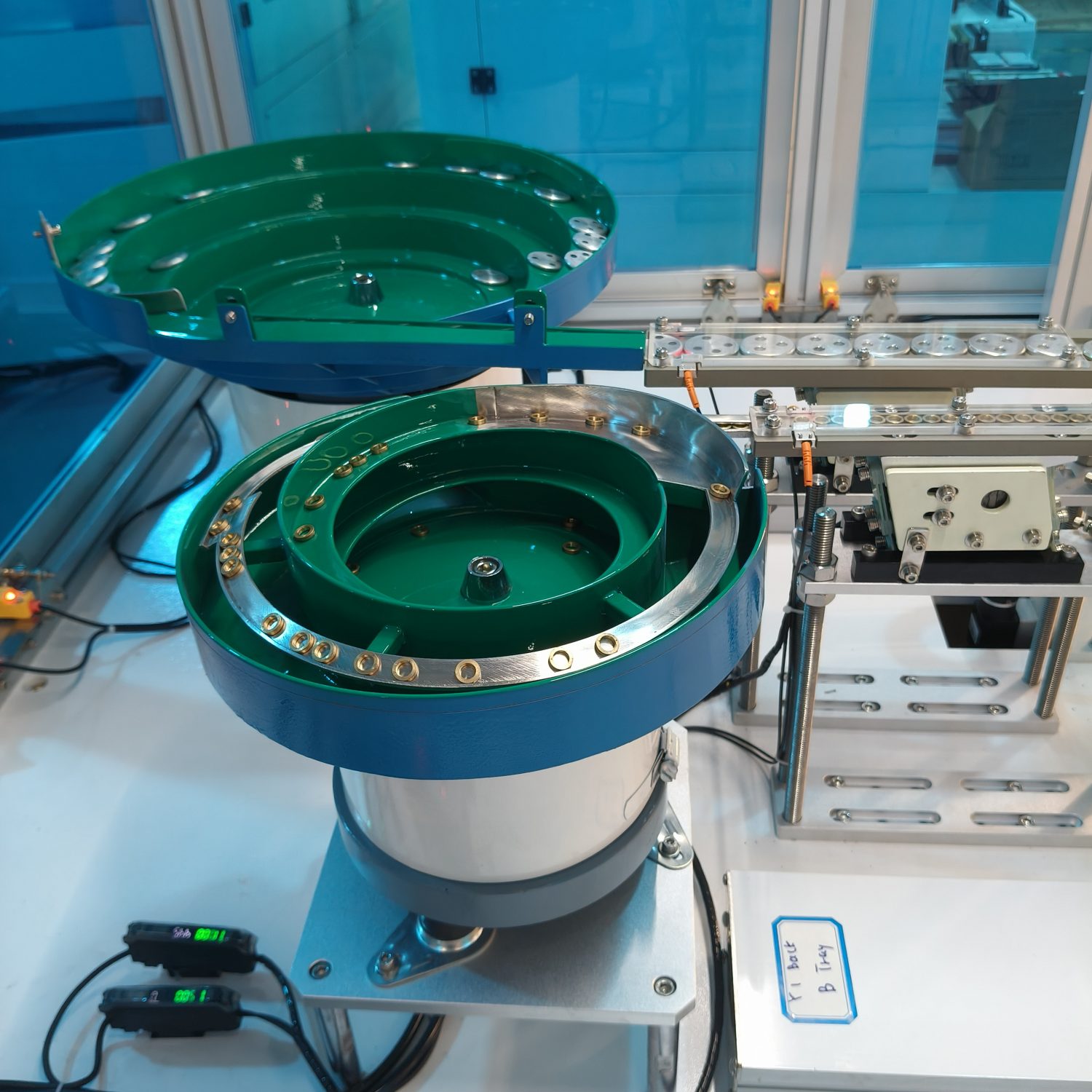

Screw Fastening Machine M1–M8 with High Speed Operation for Smart Device Assembly

In the fast-paced smart device assembly industry, efficiency and precision are pivotal to meeting mass production demands. The Screw Fastening Machine M1–M8 with High Speed Operation perfectly caters to these needs, integrating the wide compatibility of M1–M8 screw specifications and the efficiency of high speed operation to deliver consistent, reliable fastening results for smart phones, tablets, wearables, and other intelligent hardware.

High Speed Operation: Boosting Assembly Efficiency

High speed operation is the core advantage of this machine, addressing the efficiency bottleneck of traditional screw fastening in smart device assembly. With a fastening speed of up to 120 screws per minute, it significantly outperforms manual operation (typically 20–30 screws per minute) and common semi-automatic equipment. The high-speed servo motor and precision transmission system ensure stable operation without compromising accuracy, avoiding errors caused by rapid movement. This efficiency improvement directly reduces production cycle time, enabling manufacturers to meet tight delivery schedules and scale up production capacity easily.

M1–M8 Wide Compatibility: Adapting to Diverse Smart Devices

The M1–M8 screw size range provides exceptional versatility for smart device assembly. Smart devices feature various screw specifications—from tiny M1 screws for wearable sensors to M8 screws for smart home appliance casings. This machine can quickly switch between different screw sizes by replacing the driver bit and adjusting parameters, without the need for complex equipment modifications. The adjustable torque control (0.1–5 N·m) matches the fastening requirements of different components, preventing over-tightening that may damage delicate circuits or under-tightening that causes assembly looseness.

Precision Design: Safeguarding Smart Device Quality

Precision is critical for smart device assembly, where components are compact and fragile. The machine adopts high-precision visual positioning technology, achieving a positioning accuracy of ±0.01mm to ensure the driver bit aligns perfectly with screw holes. The built-in torque feedback system real-time monitors and adjusts the fastening force, ensuring each screw meets the uniform torque standard. Additionally, it is equipped with fault detection functions (screw missing, floating, slipping), which automatically trigger alarms and stop operation, reducing defective products and rework costs. These precision features effectively protect the integrity of smart device components during the screw fastening process.

In summary, the combination of high speed operation efficiency, M1–M8 wide compatibility, and precision design makes this machine an indispensable tool for smart device assembly. It provides the efficiency, versatility, and quality assurance required to meet the strict standards of the modern smart device manufacturing industry.