Views: 0 Author: BBA AUTOMATION Publish Time: 2025-03-27 Origin: BBA AUTOMATION

In modern manufacturing, precision soldering equipment plays a crucial role in ensuring high-quality electronic assembly and production efficiency. As industries demand smaller, more complex electronic components, advanced soldering technology has become essential for achieving consistent results. From automated soldering systems to specialized micro-soldering tools, precision-driven solutions are transforming production lines and enhancing productivity.

One of the key benefits of precision soldering equipment is its ability to deliver highly accurate and repeatable solder joints. Unlike manual soldering, which is prone to human error, automated systems ensure that each connection meets strict quality standards. This results in fewer defects, improved electrical conductivity, and enhanced product reliability.

Time efficiency is critical in large-scale manufacturing. Automated soldering systems, such as reflow soldering and selective soldering machines, significantly reduce production times by handling multiple joints simultaneously. These systems optimize the soldering process by maintaining consistent temperatures and applying solder with precision, allowing manufacturers to meet tight deadlines without compromising quality.

Traditional soldering methods often lead to excessive material usage and unnecessary waste. Precision soldering equipment minimizes this issue by applying solder with exact measurements, reducing excess material and lowering costs. Additionally, lead-free soldering techniques help manufacturers comply with environmental regulations while maintaining production efficiency.

Ensuring product durability and performance is a top priority in industries such as automotive electronics, medical device manufacturing, and consumer electronics. Advanced soldering technology includes features such as temperature control, flux management, and automated inspection, which help maintain the highest quality standards. This prevents common defects such as cold joints, bridging, and oxidation-related failures.

| Product Title | Suitable for various industries |

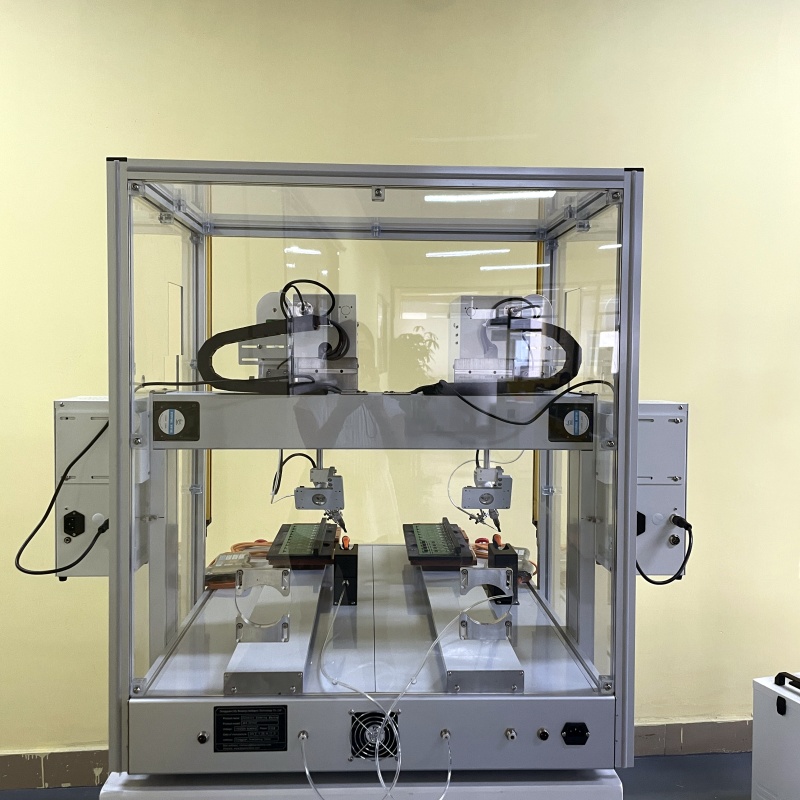

| desktop soldering robot | Electro-Acoustic |

As electronic components continue to shrink in size, micro-soldering tools and high-precision soldering techniques have become essential. Whether in printed circuit board (PCB) assembly or fine-pitch component soldering, precision equipment ensures accurate and secure connections, even in the most compact designs.

By integrating precision soldering equipment into production processes, manufacturers can significantly boost efficiency, reduce waste, and maintain high-quality standards. As the demand for advanced soldering technology continues to rise, industries that embrace these innovations will remain at the forefront of technological advancement and productivity.