Views: 0 Author: BBA AUTOMATION Publish Time: 2025-02-28 Origin: BBA AUTOMATION

In the realm of precision engineering, where high-quality results are non-negotiable, the tools used for assembly and repair play a pivotal role. One such essential tool is the hot air gun. Widely used in electronics, automotive, and other industries, the hot air gun offers precision and versatility, making it indispensable for tasks such as soldering, desoldering, and heat shrinking. This article delves into the reasons why hot air guns are a crucial asset in precision engineering.

| Product Title | Applicable Industries |

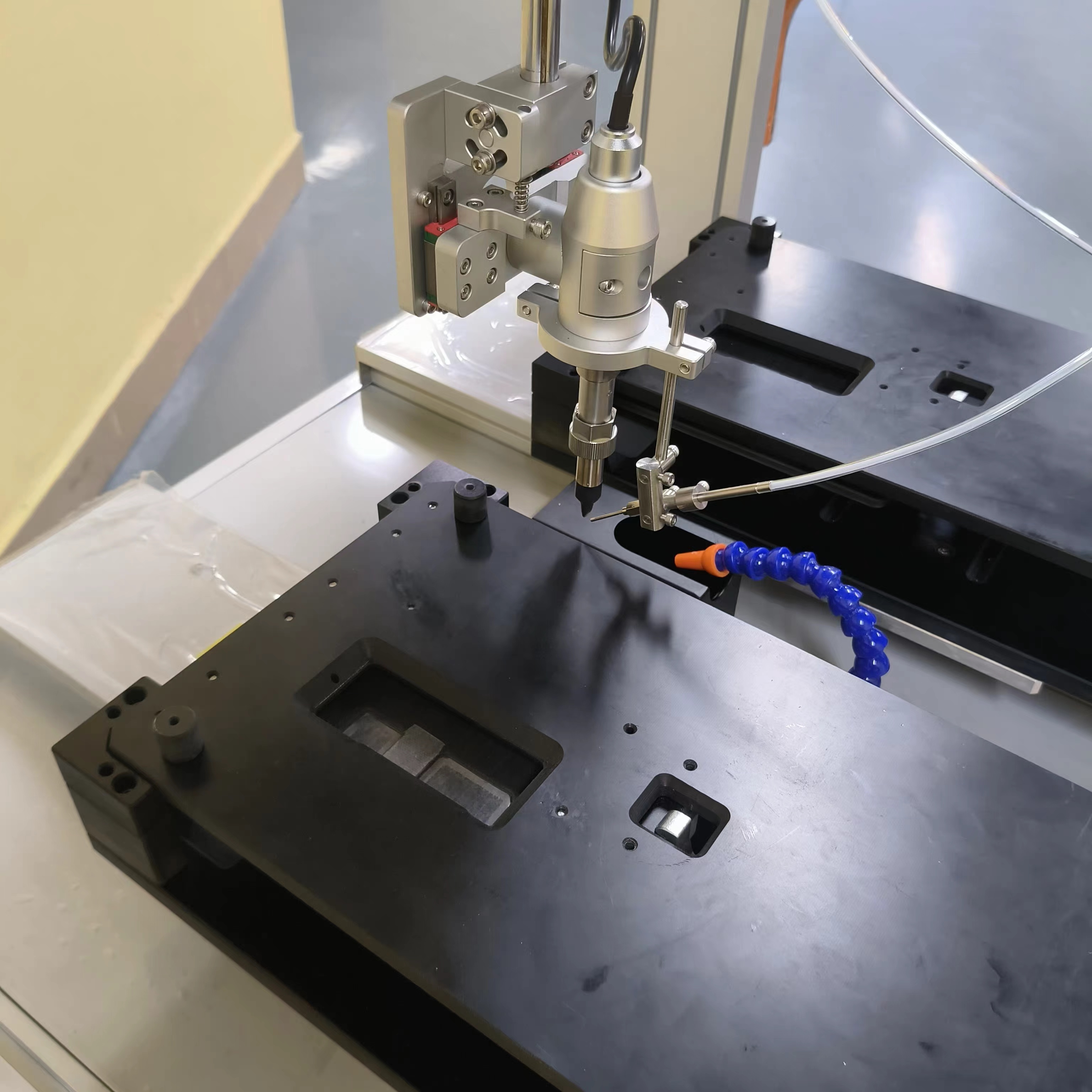

| automatic soldering robot | Electro-Acoustic |

One of the primary reasons the hot air gun is so valued in precision engineering is its versatility. It can be used across a variety of tasks that require precise heating, such as desoldering electronic components, heat-shrinking tubing, and even curing certain materials. The ability to adjust the temperature and airflow makes the hot air gun suitable for a wide range of delicate applications, ensuring that engineers can use it for different tasks without damaging surrounding components.

The hot air gun’s temperature control and adjustable airflow provide the precision needed for intricate tasks. In electronic component repair, for example, overheating can cause irreversible damage to sensitive parts like circuit boards. Hot air guns are equipped with settings that allow engineers to fine-tune the heat, ensuring that only the specific area that needs to be worked on is affected. This control is essential when dealing with components that require careful handling, such as microchips or delicate surface-mount devices (SMDs).

When it comes to soldering or desoldering small components, the hot air gun is a game-changer. It enables a quick and efficient process, especially in situations where a soldering iron might not be precise enough. The hot air gun’s even heat distribution ensures that solder joints melt evenly without overheating the surrounding components. Additionally, it allows for easy removal of components, reducing the risk of damage to the board or other parts during the process.

Unlike traditional soldering irons, hot air guns can be safer to use in certain situations, particularly in environments where direct contact with hot surfaces should be avoided. With the right protective attachments, the risk of burns or accidents is minimized. Moreover, many modern hot air guns come with ergonomic designs, making them comfortable to handle during long sessions. This reduces operator fatigue and enhances both safety and performance.

In precision engineering, where accuracy and quality are critical, the hot air gun is an indispensable tool. Its versatility, precise control, and efficiency make it essential for tasks like soldering, desoldering, and heat shrinking, among others. As industries demand higher standards of precision and faster production times, the role of the hot air gun in providing reliable, high-quality results is more important than ever.