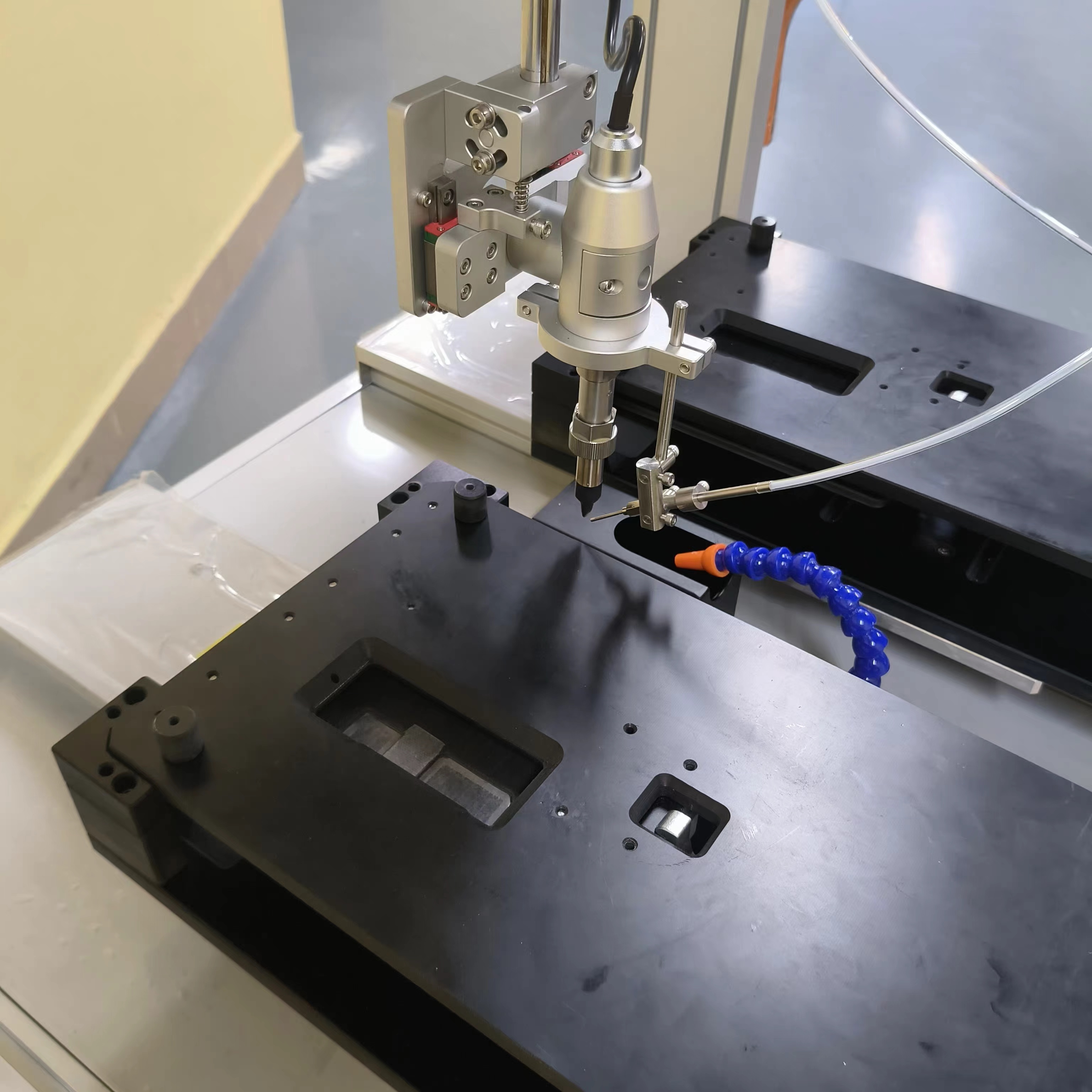

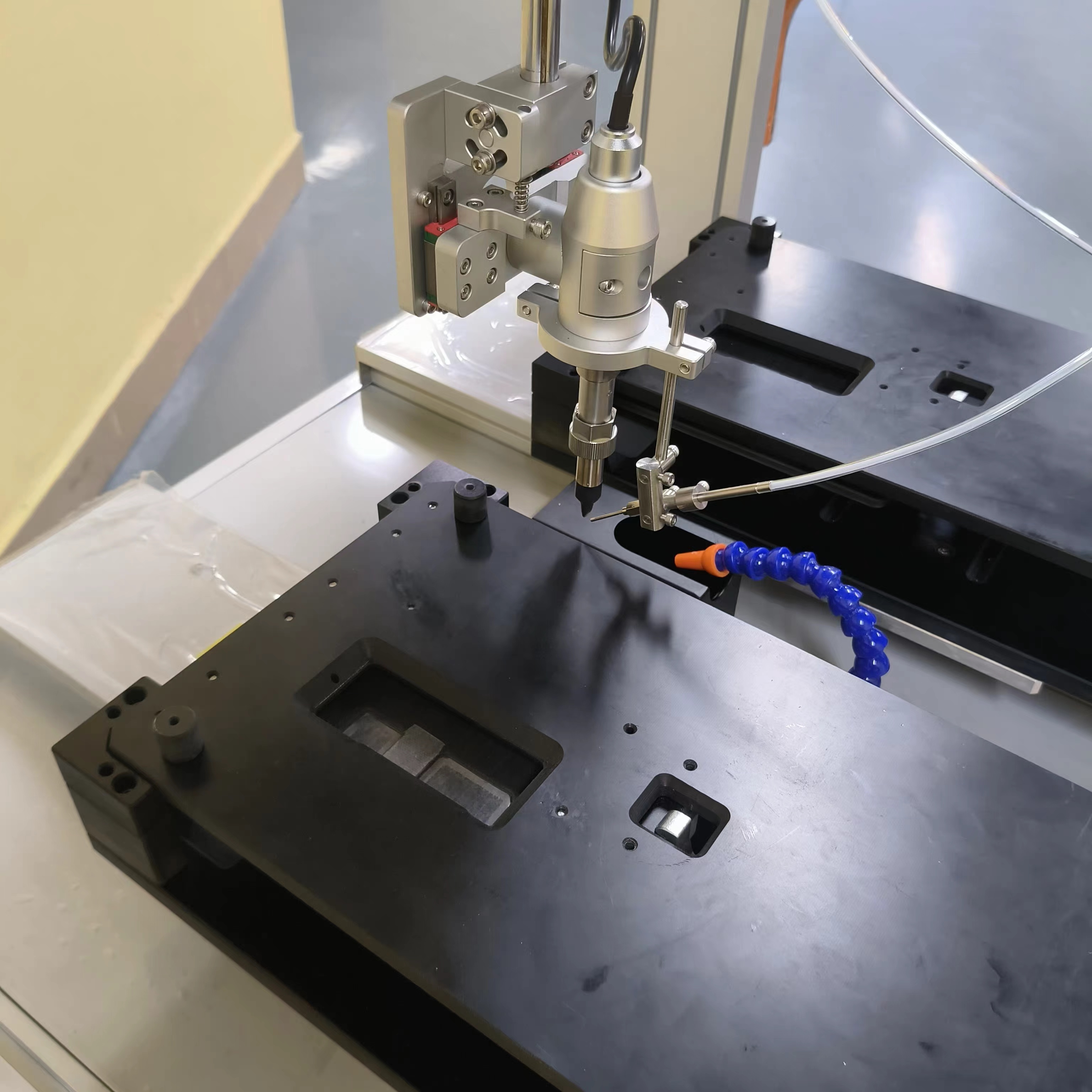

Welding Robot XYZ Axis Style with Safety Cover, Ideal for PCB Assembly

In electronic manufacturing, PCB assembly requires a balance of motion flexibility, operational safety, and soldering precision—especially for dense, miniaturized PCBs. The Welding Robot XYZ Axis Style with Safety Cover perfectly meets these demands, integrating the multi-directional mobility of XYZ Axis Style with the reliable protection of Safety Cover to deliver consistent, secure soldering results for various PCB components.

XYZ Axis Style: Flexible Motion for Complex PCB Layouts

The XYZ Axis Style structure is the core of the robot’s adaptability in PCB assembly. Unlike single or dual-axis equipment, it enables three-dimensional linear movement, allowing the soldering head to easily access hidden or angled solder points—such as the joints of surface-mounted components (SMD) or the edges of rigid-flex PCBs. With smooth motion control and adjustable speed (0.4–6mm/s), the robot navigates precisely between dense component arrays without interference, ensuring each solder pad (as small as 0.2mm) is targeted accurately. This flexibility makes it suitable for diverse PCB types, from consumer electronics PCBs to industrial control PCBs, adapting to different assembly requirements seamlessly.

Safety Cover: Reliable Protection for Workshop and Operators

The integrated Safety Cover addresses a key safety concern in PCB assembly workshops. Soldering processes involve high temperatures and potential solder splatters, which pose risks to operators and can damage nearby components. The fully enclosed Safety Cover forms a protective barrier, preventing direct contact with the high-temperature soldering head and blocking splatters. Equipped with safety interlocks, it automatically shuts down the robot when the cover is opened, eliminating accidental injuries. This design not only complies with global occupational safety standards but also keeps the workshop environment clean, avoiding contamination of sensitive PCB components.

| Product Label | Applicable to multiple sectors |

| robotic soldering machine | Automotive Electronics |

PCB-Centric Adaptability: Streamlining Production Workflows

Optimized for PCB assembly, the robot offers practical features to boost production efficiency. It supports adjustable soldering temperatures (220°C–480°C), matching the heat requirements of different PCB materials (e.g., FR-4, polyimide) and solder types. The intuitive control panel allows operators to program and store soldering parameters for 70+ PCB models, enabling quick changeovers between production tasks. Its compact structure fits seamlessly into existing assembly lines, integrating with automatic PCB feeding and conveying systems. Built-in sensors monitor the soldering process in real time, alerting operators to issues like temperature deviations or solder shortages, minimizing downtime.

In summary, the fusion of XYZ Axis Style flexibility, Safety Cover protection, and PCB-focused design makes this robot indispensable for PCB assembly. It delivers the precision, safety, and efficiency needed to meet the strict quality and safety standards of modern electronic manufacturing.